In the 1960s, General Mills developed new types of thermoplastics based on amorphous polyamides. At the end of the 1970s, Henkel KGaA bought General Mills and in the 1980s a project group started to develop areas of application for this new type of materials.

Paul Ranft, the later founder and managing director of OptiMel, joins the project group as technical sales representative and further projects in the field of cable bonding are initiated.

With the increased use of electronics in the automotive sector, the need for protection against moisture increases. A project of the PSA Group together with Henkel on the longitudinal impermability of cable harnesses and connectors can be carried out successfully.

For this, Paul Ranft (left,founder and partner of OptiMel), Jean-Louis Requin (right, today project manager at OptiMel), Bettina Becker (team leader project development at Henkel) and colleagues received the Henkel innovation award.

The previous project group is restructured into a regular department within Henkel. Further projects in the field of electronics moulding on the French and European automotive market are being implemented together with an external machine engineering partner.

Henkel commissions Paul Ranft to found a new company as a system provider for the newly developed Low Pressure Moulding process. OptiMel is founded and moves into its first premises in Iserlohn.

The first machine developed and built by OptiMel is sold. The OM 2000 series is an all-rounder and will be continuously expanded in the following years and used successfully for numerous projects with a wide variety of requirements.

At the end of the 1990s, the partner network began to be set up with the first foreign representations in Switzerland and Denmark. In the course of the following years this was be continuously expanded.

As part of a strategic realignment, Henkel sells the chemicals business (Cognis - now BASF) as well as all mechanical engineering companies.

Paul Ranft takes over OptiMel, which from now on acts as an independent specialist for Low Pressure Moulding and continues to act as an official partner of Henkel.

The OptiMel team is growing steadily and with it the space requirements. We move to our new company building at Almeloer Str.

With a new machine series, a compact solution is brought onto the market that combines convenient processing and efficient pricing for small to medium-sized series productions.

OptiMel becomes a training company - we want to give young people the opportunity to receive well-founded training within the complexity and flexibility of a medium-sized industrial company and at the same time strengthen our own team.

OptiMel starts its own tool shop with a CNC machine and a new employee. This is primarily intended to further increase the flexibility in the creation of sample tools as well as adjustments and changes.

Extruder technology finds its way into Low Pressure Moulding. OptiMel is developing a special system for adapting to the requirements of the technology. In this way, the material-saving advantages of the system can be used and at the same time the requirements for processing sensitive electronics can be optimally taken into account.

Eva Ranft, daughter of Paul Ranft, who has been working for the company since 2007, is appointed as a further managing director. She started as a trainee in the administrative area, was responsible for production planning in the machine area, marketing and later also for personnel, work safety and quality, among other things.

Since 2013 as authorised signatory and partner.

The company's own tool shop is being expanded - three employees have been working at a second location since January 2018.

All of them have many years of experience, two of whom had previously worked on the supplier side for OptiMel in toolmaking for over 10 years.

Paul Ranft retires from the management and active business and Eva Ranft becomes the sole managing director.

Two innovations were presented at productronica in Munich.

A new logo combines recognisability with a new lightness and creates a brand presence in line with the innovative and flexible company startegie.

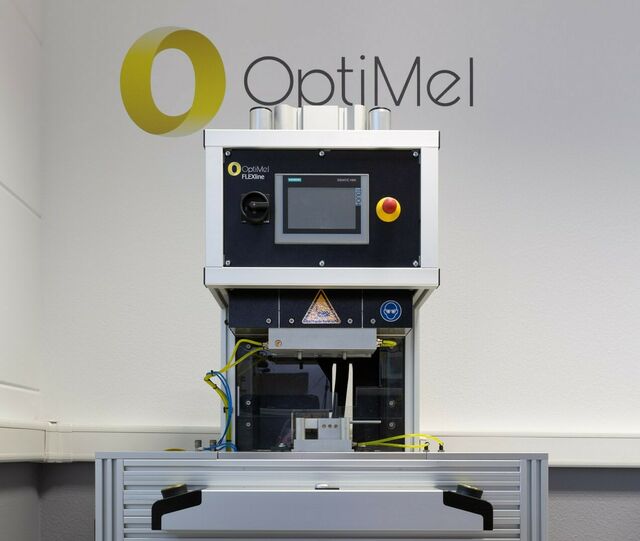

In addition, in order to take into account the developments in recent years away from the standard machine types towards a modular, flexible system, instead of the previous machine types, 3 new machine series are being launched - based on the BASEline, FLEXline and CUSTOMline, all requirements will be implemented individually in the future.

OptiMel presents a new Low Pressure Moulding system with integrated induction equipment. This means that for the first time, adhesion can also be reliably created on metallic components in one manufacturing process, thereby eliminating one of the previous limits of the technology.

The system receives a utility model protection.

OptiMel becomes a climate-neutral company.

With the creation of a CO² balance, continuous reduction and compensation, we live up to our ecological responsibility.