For some years now, special hotmelt extruders have been used in the LPM process. They make it possible to melt the moulding materials very quickly and on demand.

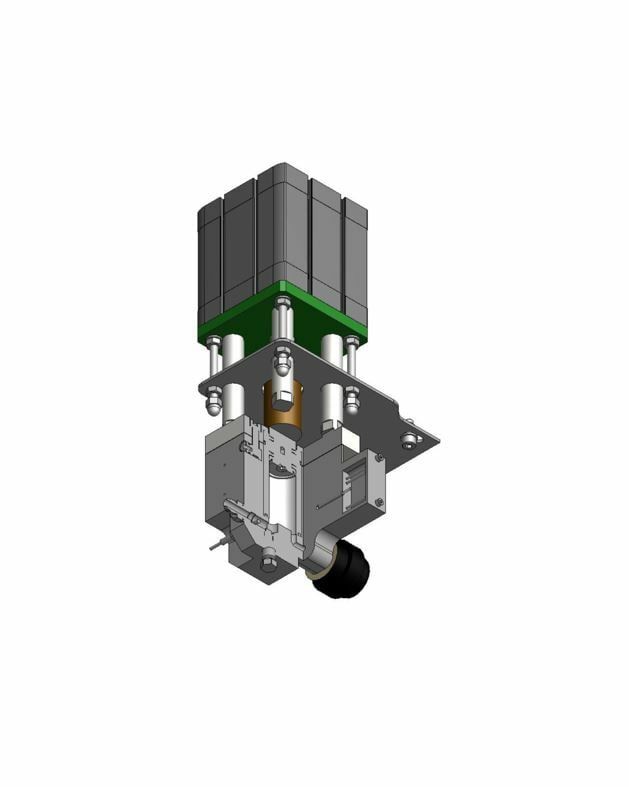

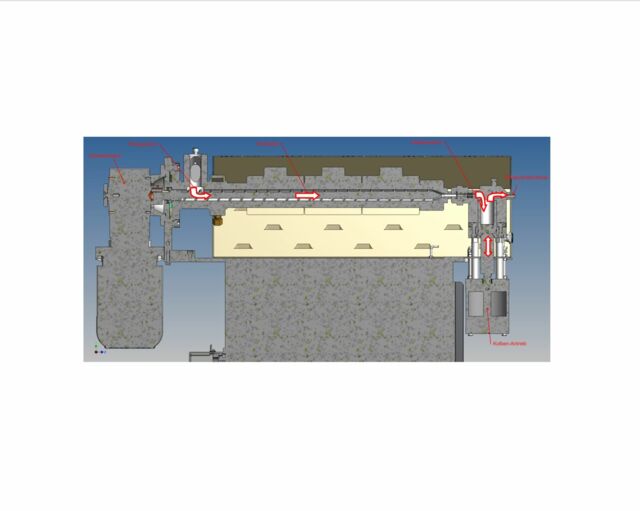

OptiMel has developed an extruder system that is specially adapted to the conditions and parameters in electronics encapsulation. A special design uses the advantages of the extruder when melting the materials and realises the injection via an additional piston unit.

With this process, pressure peaks can be avoided and the advantages of extruders can be combined with the requirements for processing sensitive electronic components.

The LPM extruder can be combined with all FLEXline and CUSTOMline machines.

- Special extruder design for LPM technology

- Gentle, on-demand melting

- Can also be retrofitted to all FlexLine machines

Specifications

Melting capacity: ca. 5 kg/h (depending on material type)

Heating zones: 6, separately controllable

Temperature range: up to 250 °C

Temperature range feeder: max. 30°C

Heating time: < 60 min (depending on material and tank level)

Conveyor: Screw with downstream piston unit

Screw speed: max. 130/min

Filling volume piston unit: 60g/100g (or on request)

Control: Siemens 1200 SPS client - controlled by machine

Material pressure plunger unit: 1- 37 bar

Extruder pressure limited to: 100 bar

Noise emission at a distance of 1 m: 62 dB(A)

Dimensions: B 500 x T 1370 x H 905 mm

Weight: approx. 200 kg

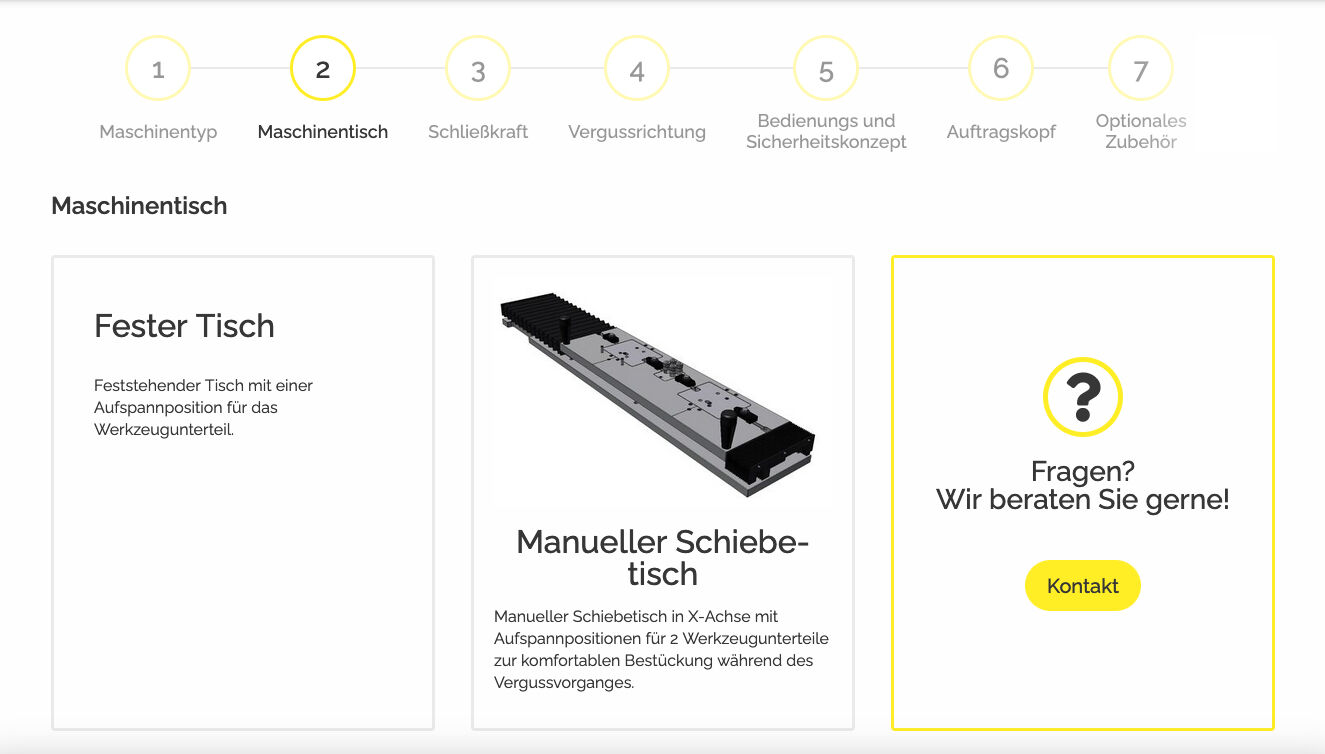

Machine configurator

Use our machine configurator to put together your individual Low Pressure Molding machine, tailored to your manufacturing processes.

Low Pressure Molding tools

The decisive factor for the technical implementation of any project is the corresponding moulding tool. Each is individually developed, designed and manufactured for the respective project.

Our experienced designers and project managers are always available to consult you!

Hot melts for electronics encapsulation

There is the right material for every application. Amongst our hotmelt granulates we also have the right material for special projects and areas of application.

Find out more about the various types of materials.

Virtual LPM studio

With our OptiMel Studio, we added a digital space to our facilities in 2020.

We are thus just as well positioned for virtual trade fairs and lecture events as we are for individual online seminars and training courses.

In addition, individual consultation appointments can also be organised. For example, you can get to know our machine system in detail, book operator and maintenance training courses or take part in a tool sampling - and all this conveniently from the comfort of your own workplace.

Do you need support in choosing the right equipment? Would you like advice on individual solutions?

We are at your disposal!