Project consulting, feasibility analysis and prototyping

At the beginning of each project, we start with extensive advice on technology and a detailed consideration of the project requirements.

We support you with feasibility analyses, adhesion tests, mould flow analysis, creation of prototypes, process design and calculation of the required production equipment.

Instructions and trainings

We impart extensive knowledge which contributes to the successful application of the technology. Technology training to identify and assess new project opportunities as well as operator and maintenance training for smooth production processes. All trainings can be carried out on your premises, with us or online.

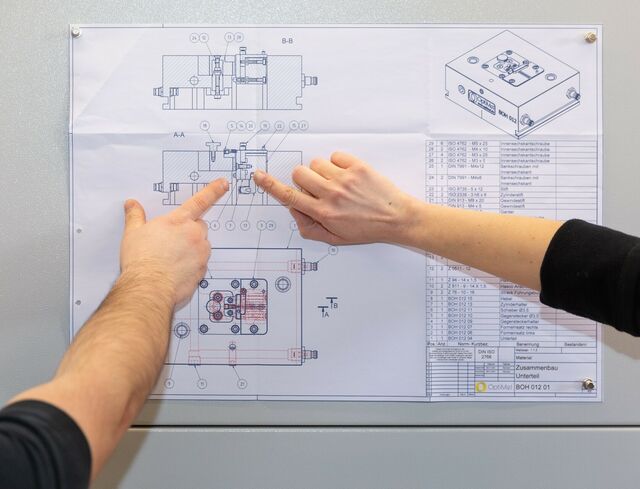

Picture: 13. Anwenderkongress Steckverbinder, Vogel Communications Group GmbH & Co. KG

Maintenance and service

Correctly understood and performed maintenance is the key to ensuring a trouble-free production process and thus avoiding unplanned production stops.

We offer various options to ensure this. Maintenance training enables your staff to carry out the necessary work properly and on time. Maintenance can alternatively be carried out by the technical staff at OptiMel - replacement equipment for bridging the production gap is available – or directly at your site.

Together with you, we will work out the appropriate alternative in each individual case, up to a maintenance contract that has been specially developed to meet your needs.

Process optimisation and support

If there is a need for process optimisation or support for ongoing projects, we are at your disposal at any time. Regardless of the type of equipment you are using, we support you with error analysis, review all parts of process, evaluate and optimise the production parameters, and offer revision and adjustment of moulding tools.

Rental machines and equipment

If you have increased production requirements for a limited period of time or if a definitive decision on the required production equipment is not yet possible, we offer the option of renting some systems at attractive conditions. Costs and processing for the regularly due maintenance are already included in the calculation.

We are there for you for all questions and requirements relating to Low Pressure Moulding technology! Whatever you need - contact us!