Why regular maintenance of hotmelt equipment is essential

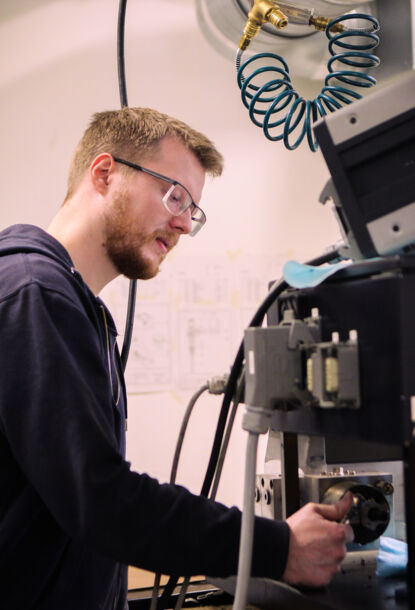

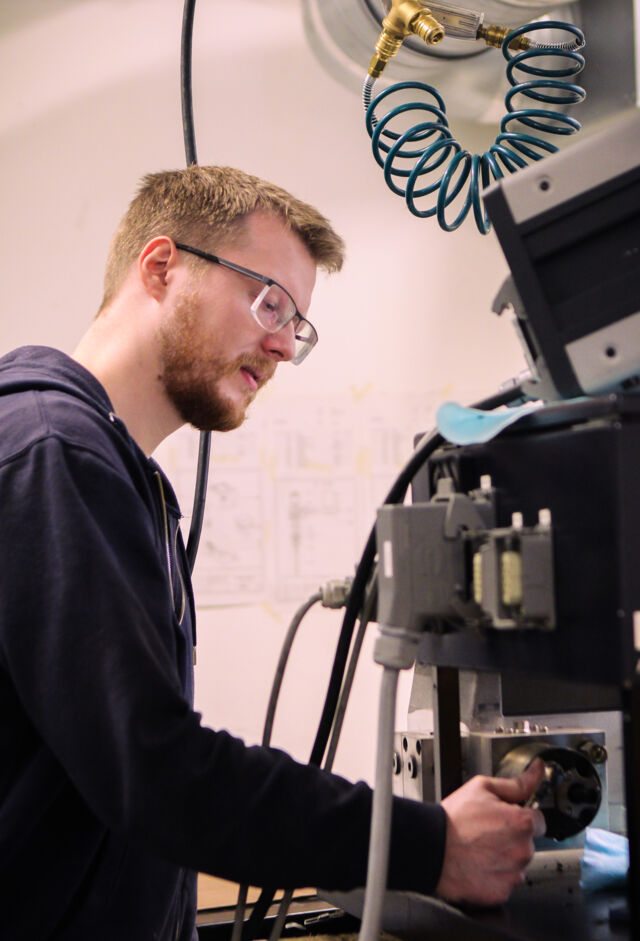

As pioneers in Low Pressure Moulding, we know: A stable and efficient production process requires the right maintenance.

Our LPM hotmelt machines are designed for precise and reliable applications. And even the best technology requires regular maintenance to consistently deliver optimal results.

Regular maintenance is especially essential in systems that operate at high temperatures. Thermal stress and deposits in the system can spread throughout the entire system without regular cleaning and maintenance, leading to unplanned outages — and in the worst case, it can also affect the quality of the processed products.

By performing preventive maintenance, you avoid unplanned downtime and ensure the quality of your products. Regular maintenance contributes to process reliability and extends the lifespan of your equipment.

Our service team supports you with tailored maintenance concepts, training for your staff, and fast response times – ensuring smooth operation of your production.

- production reliability

- process stability

- Quality assurance

- Durability of equipments

Our hotmelt services in detail

Maintenance contracts

With our maintenance contracts, you have a well-planned overview of your annual maintenance and don’t have to worry about anything. We remind you of upcoming maintenance, carry it out at fixed intervals, and you also benefit from attractive special terms..

Spare parts flat rate

Our spare parts flat rate bundles your annual spare parts needs into a fixed package – including a 10% discount. Also included: a support fee for fast telephone and video support. This way, your processes stay predictable, your machines stay available – and your costs remain under control..

Easily combined with maintenance training for your staff - online or on-site.

Maintenance & training

You want direct service on-site or ensure your own staff has the optimal know-how to efficiently carry out maintenance on the systems themselves. Then take advantage of our service, maintenance visits and training – possibly also in combination.

Rental equipment

To avoid downtime during maintenance or in case of malfunctions, we offer the possibility of loan equipment. Available at short notice and billed on a weekly basis, this option provides optimal flexibility. In addition, you benefit from special conditions for loan devices during commissioned maintenance..

Types of maintenance

Choose the service model that fits your requirements

Maintenance on demand

Short-term, on-demand assignments with no contract commitment. Ideal if you only need technical support occasionally.

Maintenance contract

Plannable service intervals with fixed response times and predictable costs – perfect for continuous production reliability.

Self maintenance with spare parts flat rate

You carry out the inspections and basic maintenance yourself, and we provide you with all the necessary original spare parts at special conditions and an additional support fee. This way, you maintain maximum flexibility and benefit from optimal support..

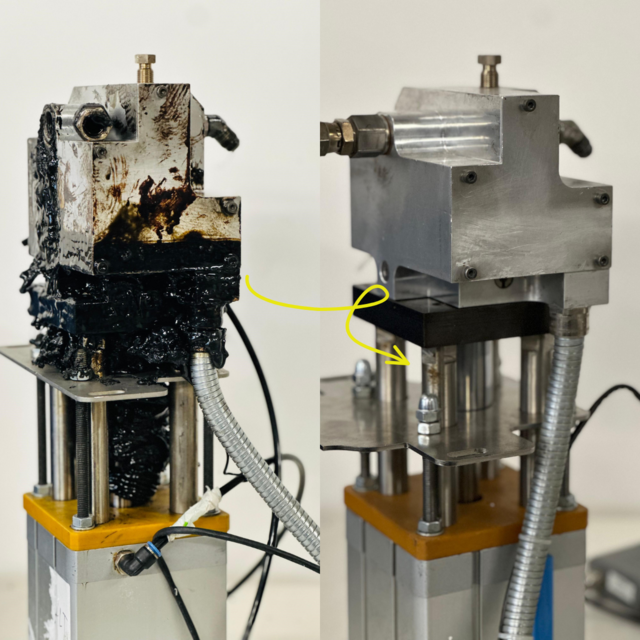

Clean components - reliable production

Heavy contamination - e.g., on a piston unit - can significantly affect the material flow. In the case shown, adhesive residues had accumulated over a long period, leading to malfunctions..

Such cases clearly show how important regular maintenance and daily visual inspections are. Those who detect leaks or material deposits early avoid unplanned downtime, maintain process stability, and reduce wear on the equipment.

Our service technicians have professionally cleaned, inspected, and restored the affected unit to perfect working condition. It is now fully operational and ready for the next production cycle.

Do you have questions or would you like a personalized maintenance offer??

Contact our service team today – we look forward to your inquiry!